Applications

Precision tooling solutions for the most demanding applications.

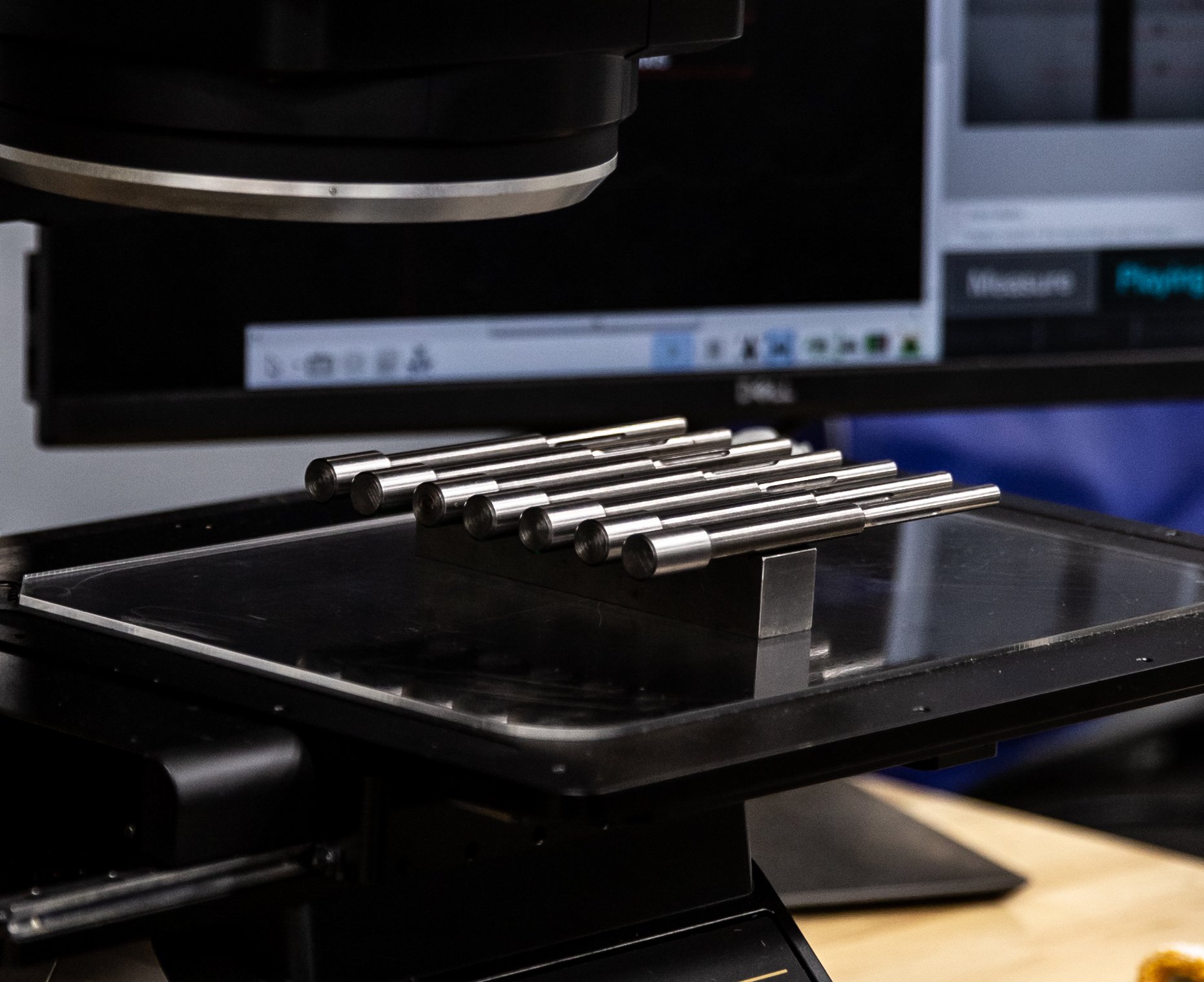

Ring Precision manufacturers high value-added, precision round tooling, and punches and dies for medical and other highly regulated industries. Our cutting-edge manufacturing processes and quality control commitment ensures tooling longevity and quality.

Medical Device & Life Sciences

We specialize in ultra-precision medical device tooling to support a wide variety of medical device and healthcare consumables. Our medical tooling and pharmaceutical tooling is used for applications such as medical and veterinary syringe bodies, single use fluid delivery products, catheters, mold cavities, pipettes for blood analyzers and testing equipment, and many others. Ring Precision uses automation and robotics in many of it’s work cells.

CNC Swiss turn machines and precision grinding capabilities allow us to produce complex square core pins or round core pins for medical injection molds, ejector sleeves and ejector pins, bushings, tooling for injection molds including drug delivery mold tooling, syringe tooling, catheter tooling, mold cavity tooling and tablet compression tooling for high-speed pill production and packaging. Durability is the hallmark of the Ring Precision tooling offering.

Our injection molding tooling expands beyond the medical device industry. Our extensive fleet of automated wire and sinker EDM machines enable us to offer complex mold cavities for your most demanding applications.

The Producto Group also specializes in precision machining and custom plastic enclosures for the medical device industry.

Drug Delivery Mold Tooling

Ring Precision specializes in ultra-precision drug delivery mold tooling, ensuring high quality and consistency to meet the stringent regulatory requirements of the medical industry. Our drug delivery mold tooling adheres to regulatory standards, including ISO 13485 for medical devices and FDA regulations, guaranteeing the superior quality, safety, and efficiency of our manufactured products. Our mold tooling is manufactured with precision to create components such as syringes, vials, cartridges, and other drug delivery devices with specific dimensions, features, and functionalities.

Aerospace & Defense

Ring Precision is an established industry leader in the manufacturing of deep draw punches and dies for complex aerospace and defense applications. Our aerospace tooling outlasts the competition with class leading precision and consistency. Whether it’s turbine airfoil blades or high precision bearing components we have the expertise to help you take your process to the next level.

Explore our precision machining capabilities in the aerospace and defense industry.

Battery

We have decades of experience supplying compaction tooling for the battery industry which is used to compact cathode mix into the battery can. Our compaction tooling offers a superior life span versus the competition. With our attention to detail, polishing, proprietary heat-treating process and world class inspection we have what it takes to keep your operation running around the clock.

Food & Beverage

Ring Precision produces precision can tooling for food and beverage applications including punches & dies for blanking and drawing, cut edges and more. We have the precision EDM capabilities that allow us to produce high volume, tight tolerance tooling for every type of food and beverage application.

Learn more about our can tooling precision machining capabilities.

Diversified industrial punches & Precision Dies

Ring Precision has decades of experience manufacturing precision tooling to support many diversified industrial applications.

We also manufacture electronics tooling from contacts, connector shells, connector pins, and circuit board level components.

TOOLING EXAMPLES

Round & Shaped Punches

Pierce Punches

Punch Blanks

Embossing Punches

Draw Punches

Pilot Punches

Round & Shaped Dies

Fin Dies

Draw Dies

Piercing Dies

Forming Dies