our Highly differentiated Capabilities

We have a large, modern fleet of equipment including the latest in fully automated and robotic CNC technology.

From prototype to production and value-added reverse-engineering services, Ring Precision has a diverse range of capabilities for your most challenging needs.

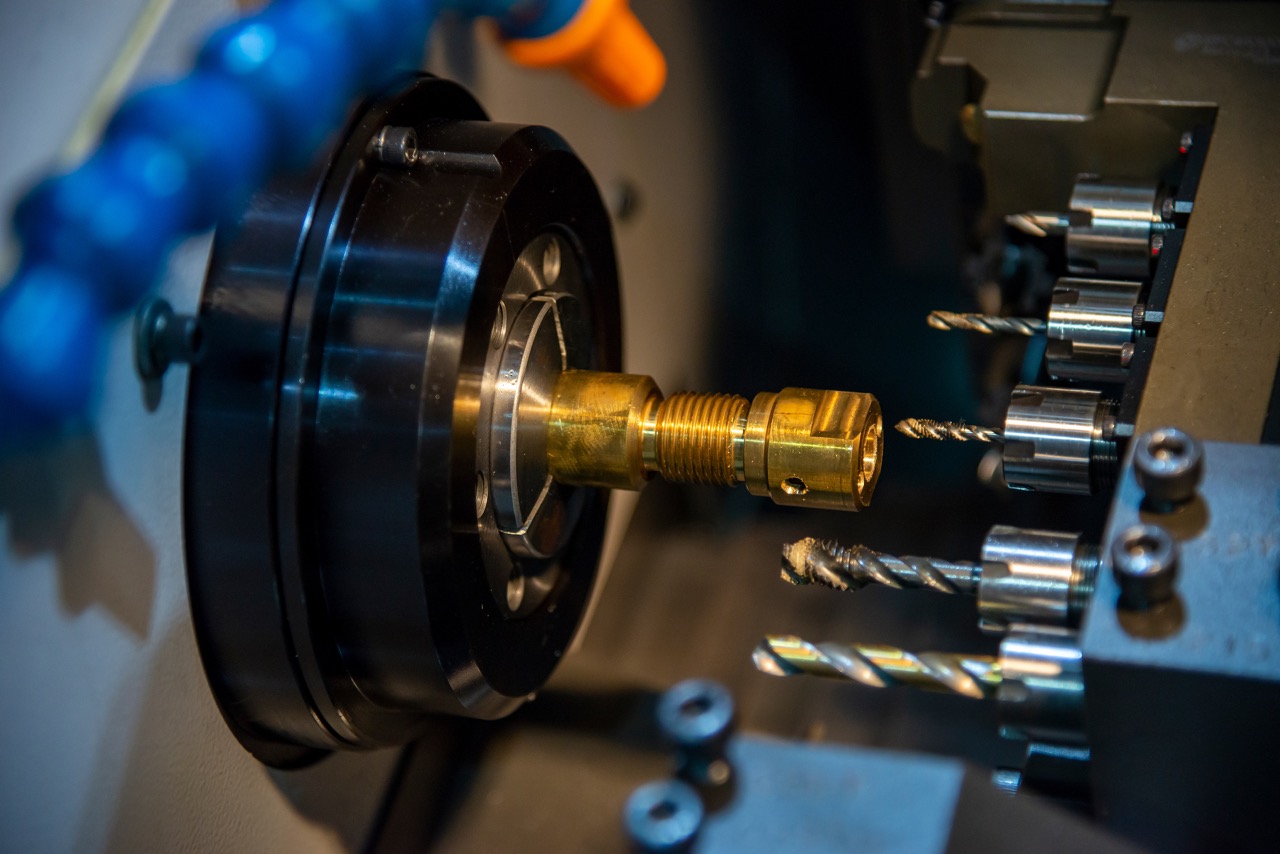

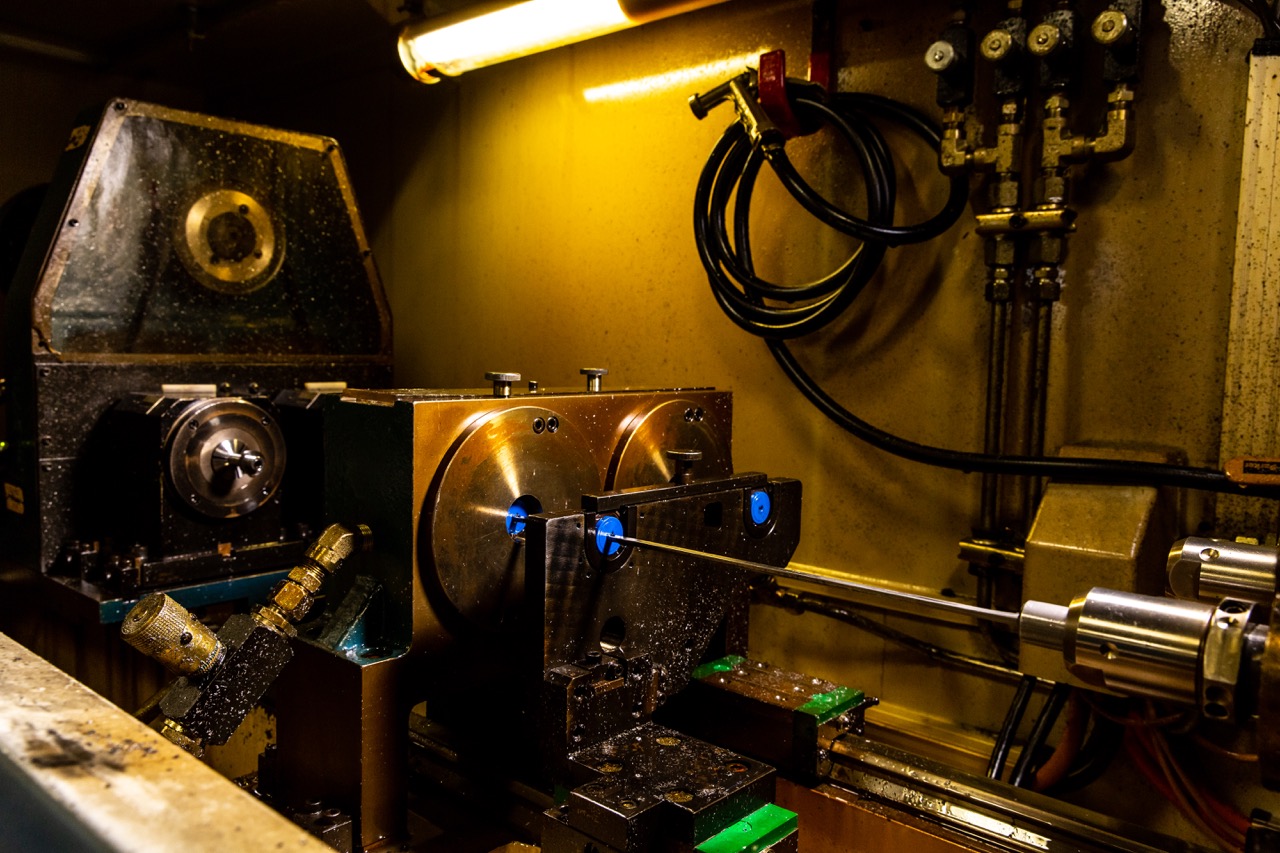

Precision Turning & Multitasking

- Swiss Lathe Turning

- Automatic Multi-Bar Raw Material Delivery, Part Length up to 20″

- 5 Axis Operation + Sub-Spindle up to 38mm Diameter

- Balance-Cut (Pinch) Turning Capabilities up to 38mm Diameter

- Capable of Achieving 16 RMS Precision Surface Finish

- Concentricity to 0.001, Tolerances to 0.0005

- Part Diameter up to 1.5″

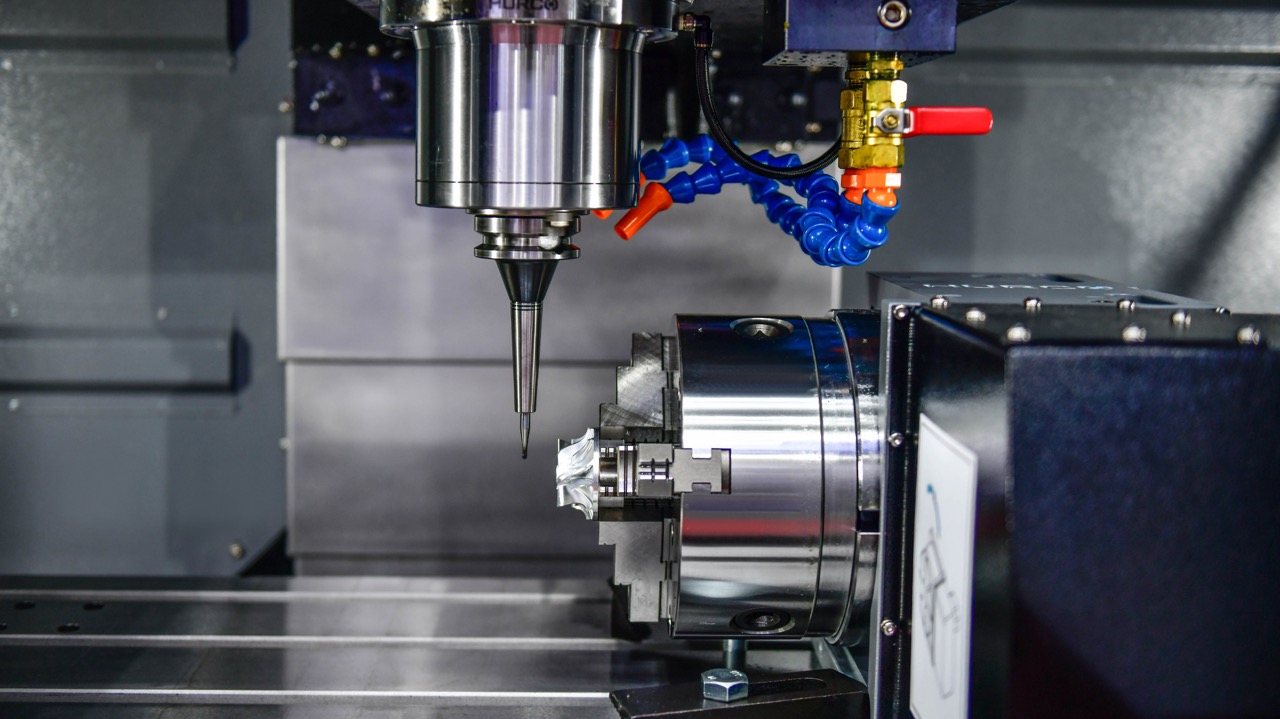

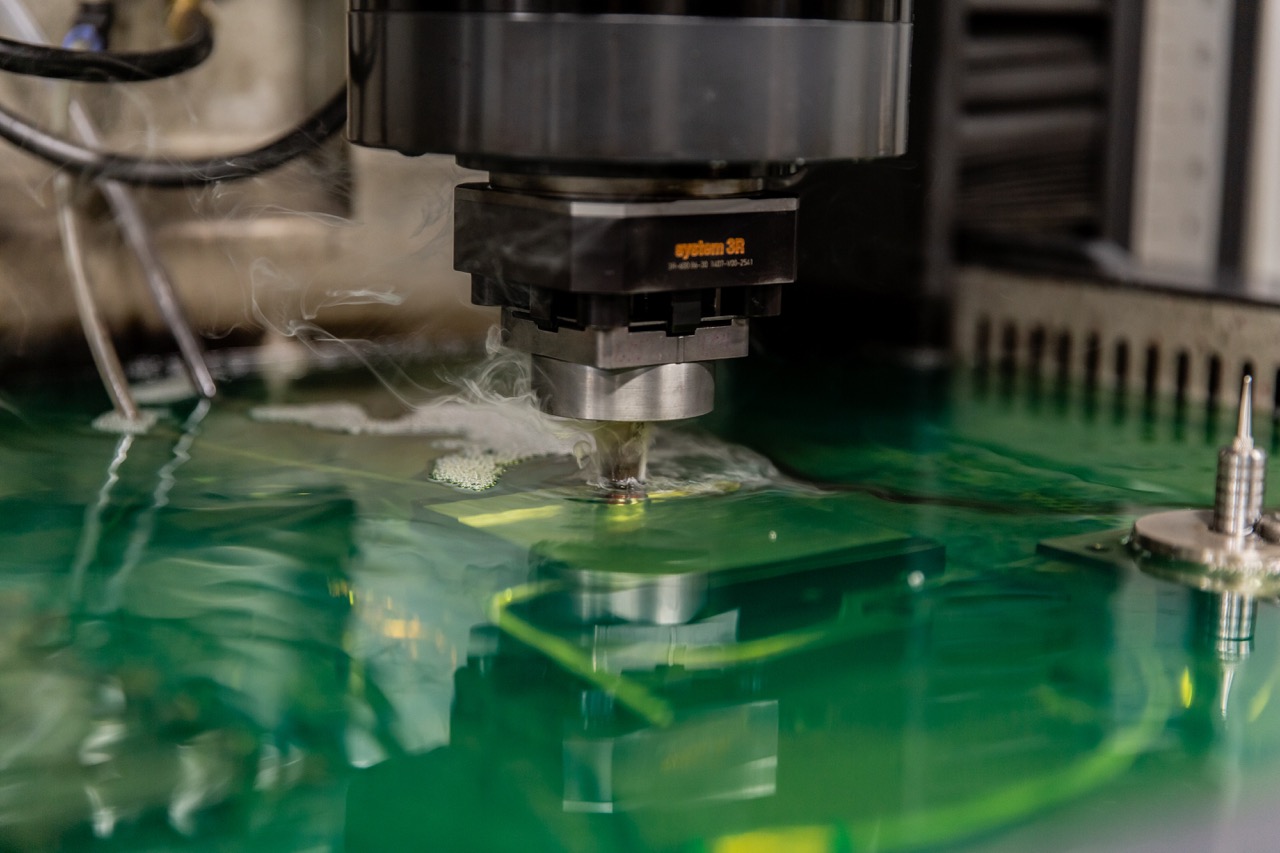

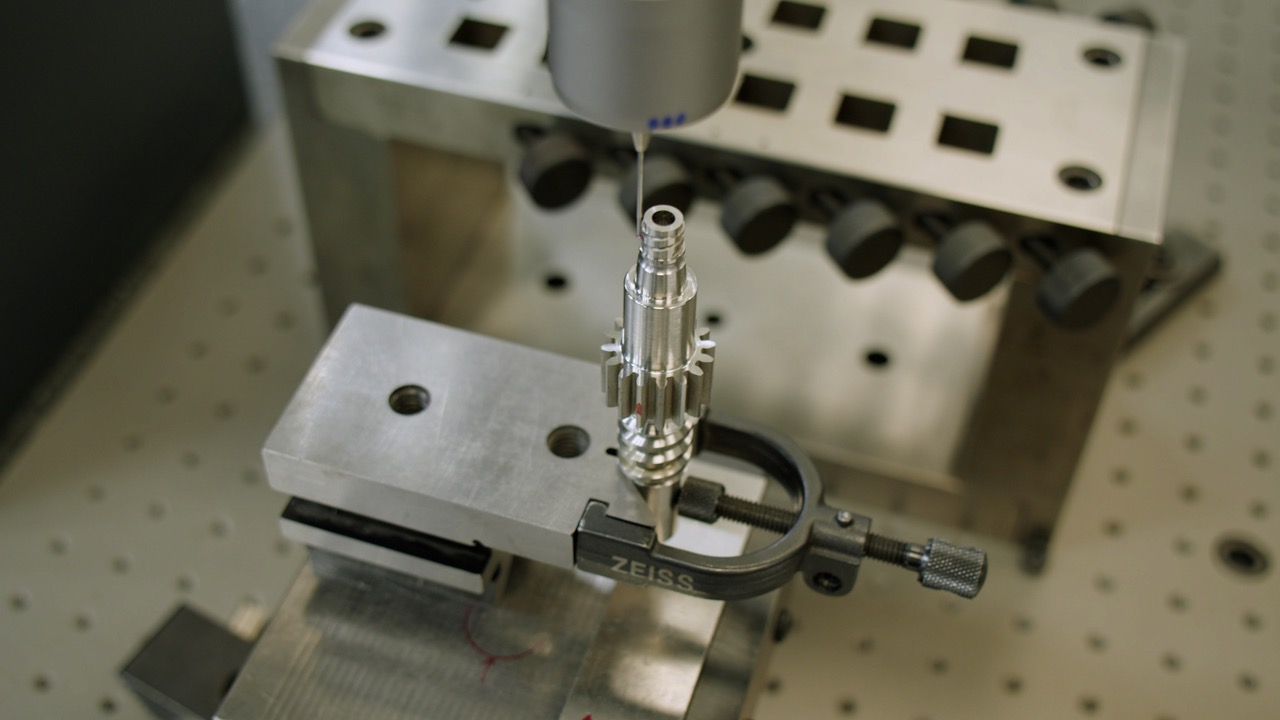

Precision CNC Machining

- Precision Milling

- 5 Axis Milling of Materials up to 62 RC/Hardness

- Thermally Cooled Hard Mill Spindles

- Shrink Fit Tooling for Improved Accuracy

- Integrated Robots for Lights Out Operation

- Part Length up to 40″

- Capable of Achieving 12 RMS Precision Surface Finish

- Concentricity to 0.0004, Tolerances to 0.0004

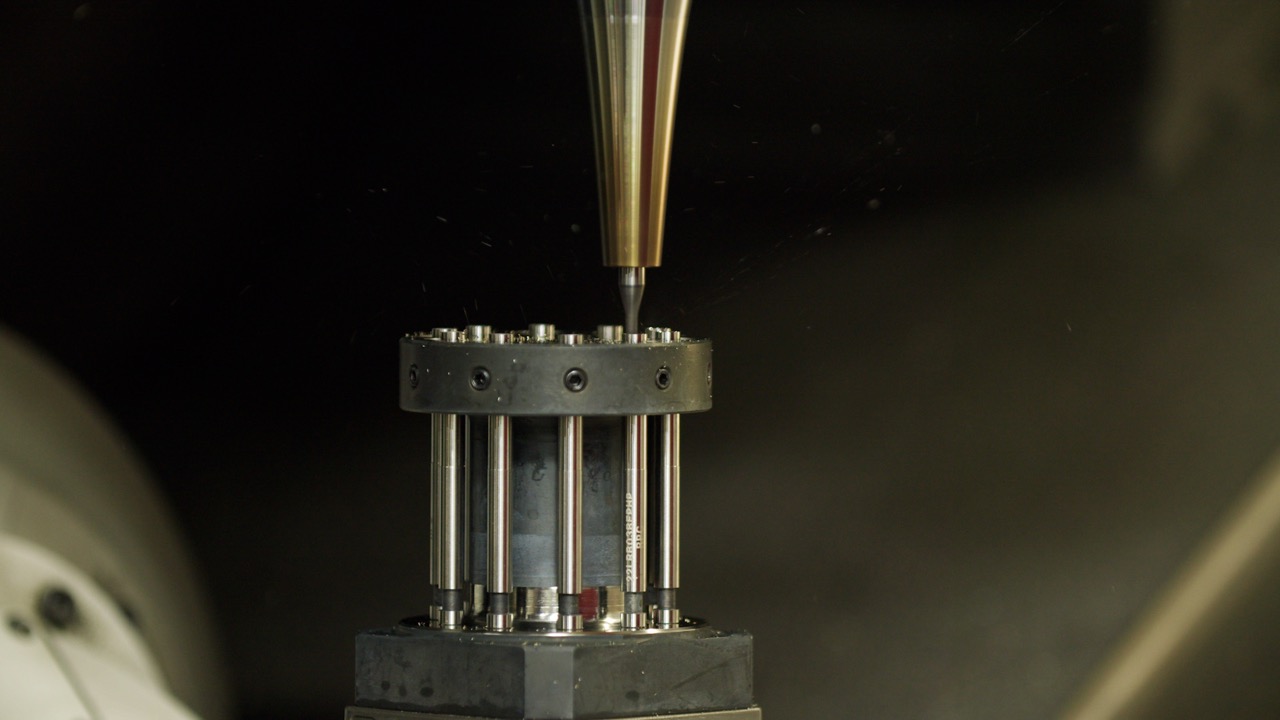

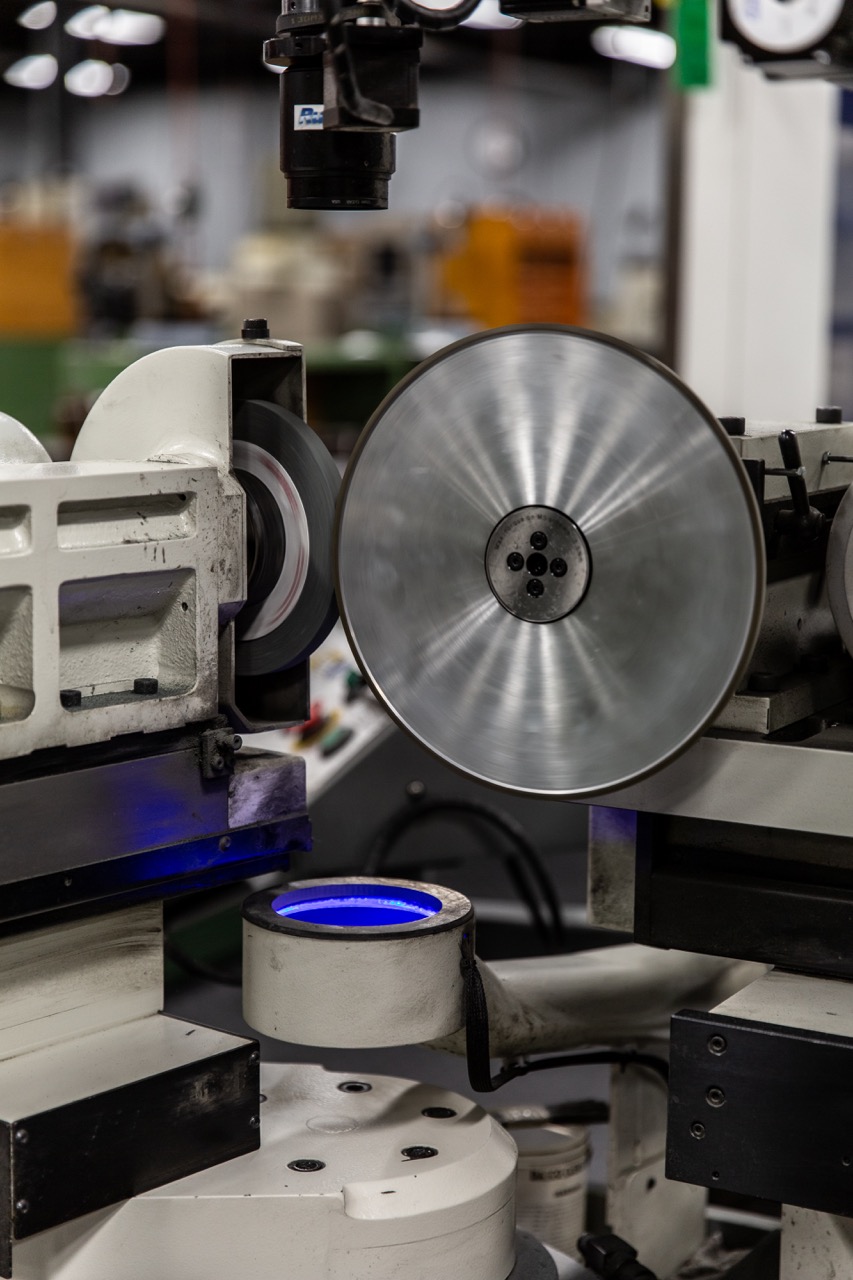

Precision Grinding

- CNC Grinding

- Complex & Unique Form Grinding

- Option To Grind with Or Without Centers

- Capable of Achieving 8 RMS Precision Ground Surface Finish

- Part Length up to 13″

- Concentricity to 0.0002, Tolerances to 0.0002

- Integrated Robots for Lights Out Operation

- CNC Jig Grinding

- Small Precision Ground I.D.’s & Forms

- Part Length up to 3″

- Capable of Achieving 4 RMS Precision Ground Surface Finish

- Custom Work Holding for Precision I.D to O.D. Accuracy

- Concentricity to 0.0002, Tolerances to 0.0002

- Flood Coolant for Improved Surface Finish

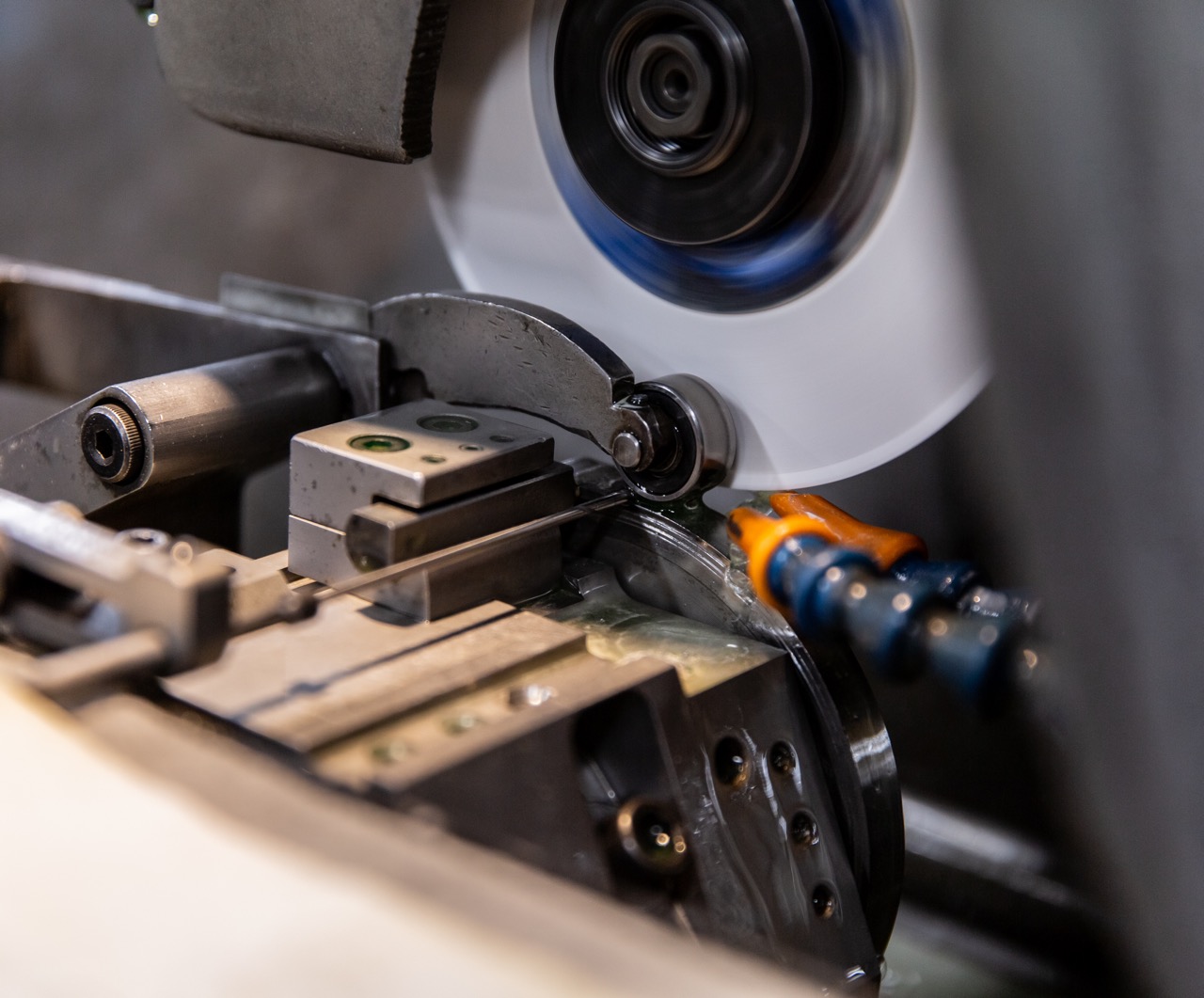

- Centerless Grinding

- Up to 15” Grind Wheel Face

- Capable of Achieving 4 RMS Precision Ground Surface Finish

- Simultaneous Grind of Multiple Diameters

- Concentricity to 0.0002, Tolerances to 0.0002

- Integrated Robots for Lights Out Operation

- CNC Surface Grinding

- Multiple Machines with up to 16” x 32” Magnetic Chuck Size

- Capable of Achieving 8 RMS Precision Ground Surface Finish

- Tolerances to 0.0002

- Automatic Grind Wheel Dressing with Size Comp

- Custom Form Grind & CBN Wheel Options Are Available

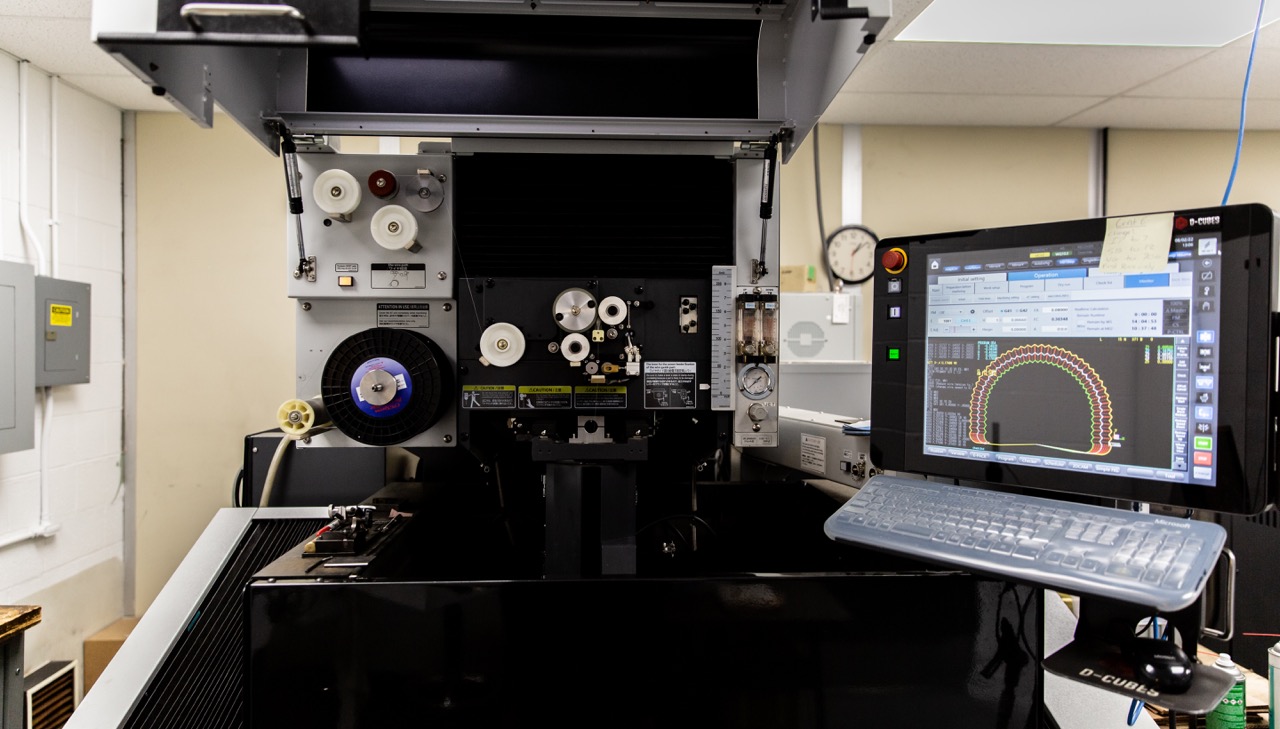

EDM Machining

- Wire EDM

- Generate Complex Unique Geometries

- Part Length up to 9″

- Capable of Achieving 16 RMS Surface Finishes

- Concentricity to 0.0002, Tolerances to 0.0002

- Lights Out Operation

- Sinker/ RAM EDM

- In-House Electrode Manufacturing

- Complex Cavity Geometry for Injection Molding Applications

- 18-21 VDI Standard EDM Surface Finish

- Concentricity to 0.0003, Tolerances to 0.0002

- Integrated Robots for Lights Out Operation

- EDM Drill

- Part Length up to 13″

- Concentricity to 0.001, Tolerances to 0.003

- 16 VDI Standard EDM Surface Finish

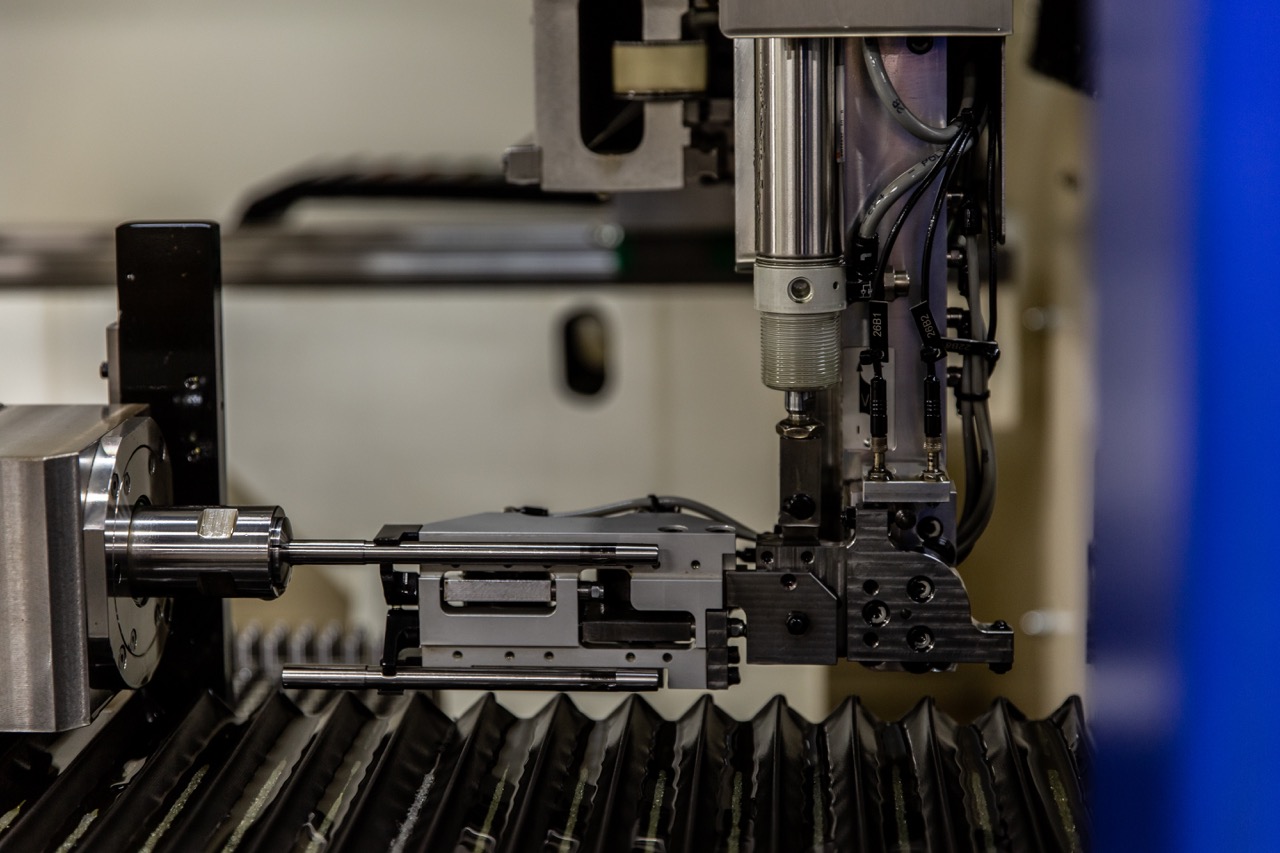

Gun Drilling

- Deep Hold Drilling Utilizing High Pressure Coolant

- Drill Diameters up to 0.625 and Part Length up to 18″

- Concentricity to 0.002, Tolerances to 0.002

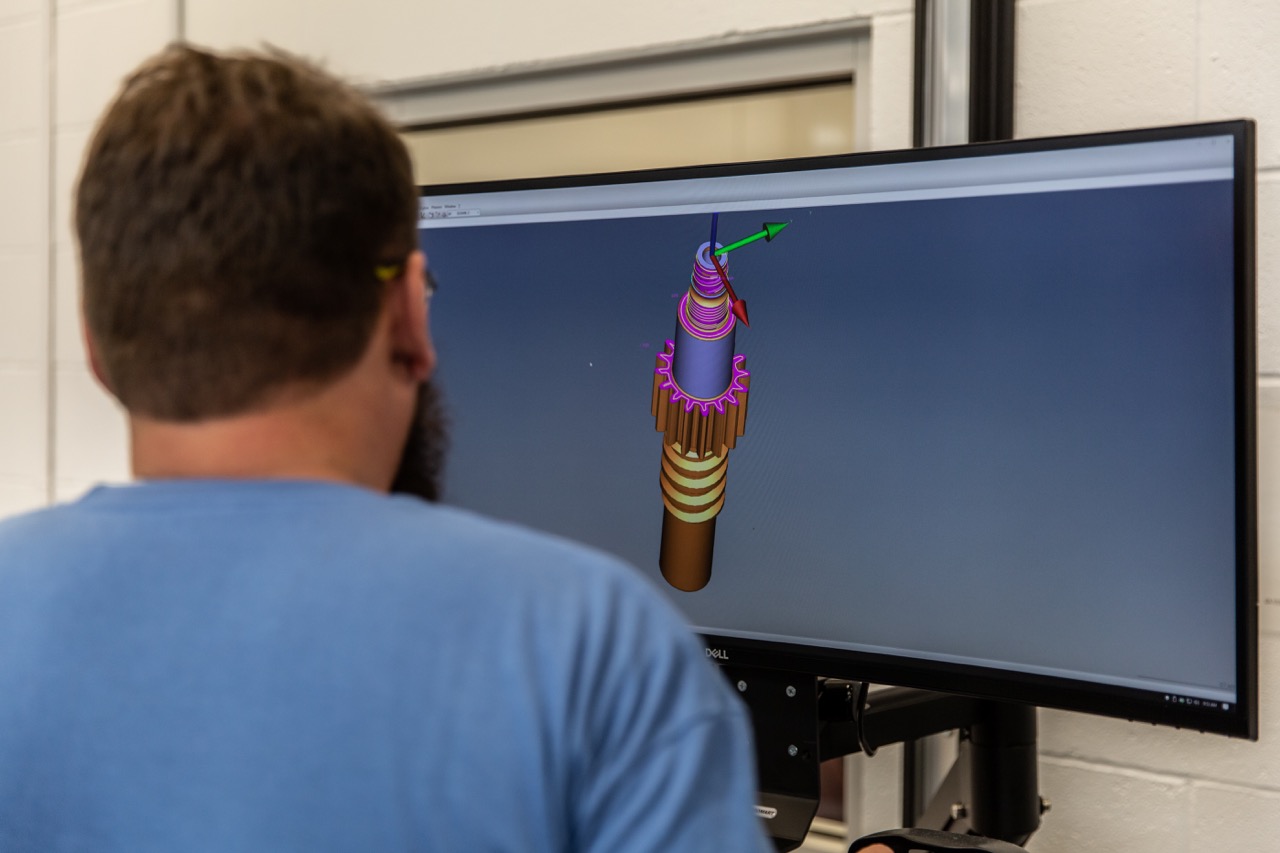

Reverse Engineering

No Drawing, No Problem. Our Engineering and Inspection Departments work together with your team to come up with a complete part drawing prior to manufacturing. When your part is manufactured, a fully documented manufacturing process is developed to ensure interchangeability each time you order.

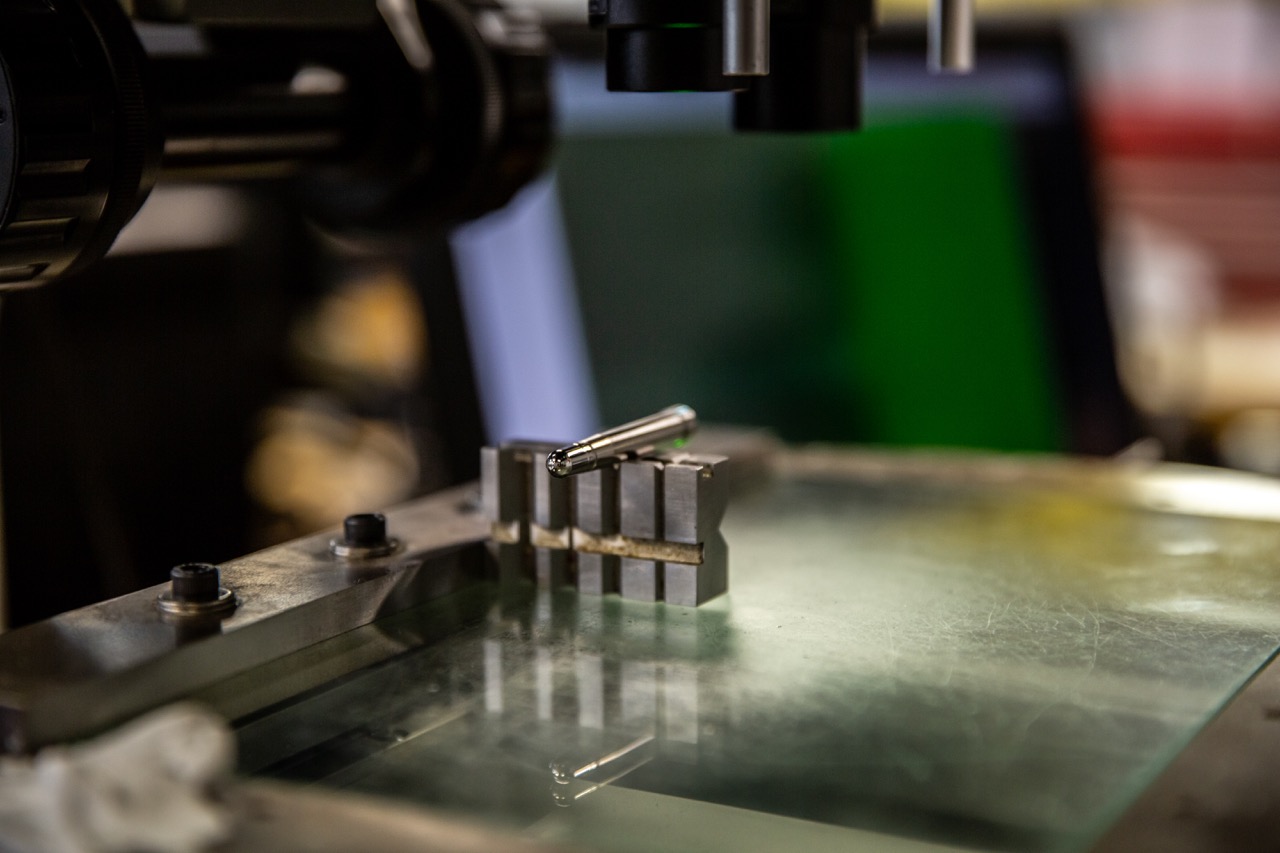

Quality & Metrology

Our Quality Control Department employs Laser, Programmable Optics, and CMM measuring equipment to assure that your parts meet the optimum (or first class) levels of satisfaction.

- Metrology

- Inspection Equipment Accuracy Maintained via Scheduled Calibration

- Inspection Reports

- Material Certification

- Heat Treat Data

- Other customized inspection reports tailored to your specific available upon request

Value Added Services

- Laser Engraving

- Part# Engraving for Identification

- Part Serialization Inspection Documentation / Traceability

- Reverse Laser Engraving for Injection Mold Cavity Identification

- Applications Include:

- Brand Identification

- Lot and Date Coding

- Part Identification and Serialized Components

- Mold Cavity, Core, and Pin Engraving

- Instrument Panels

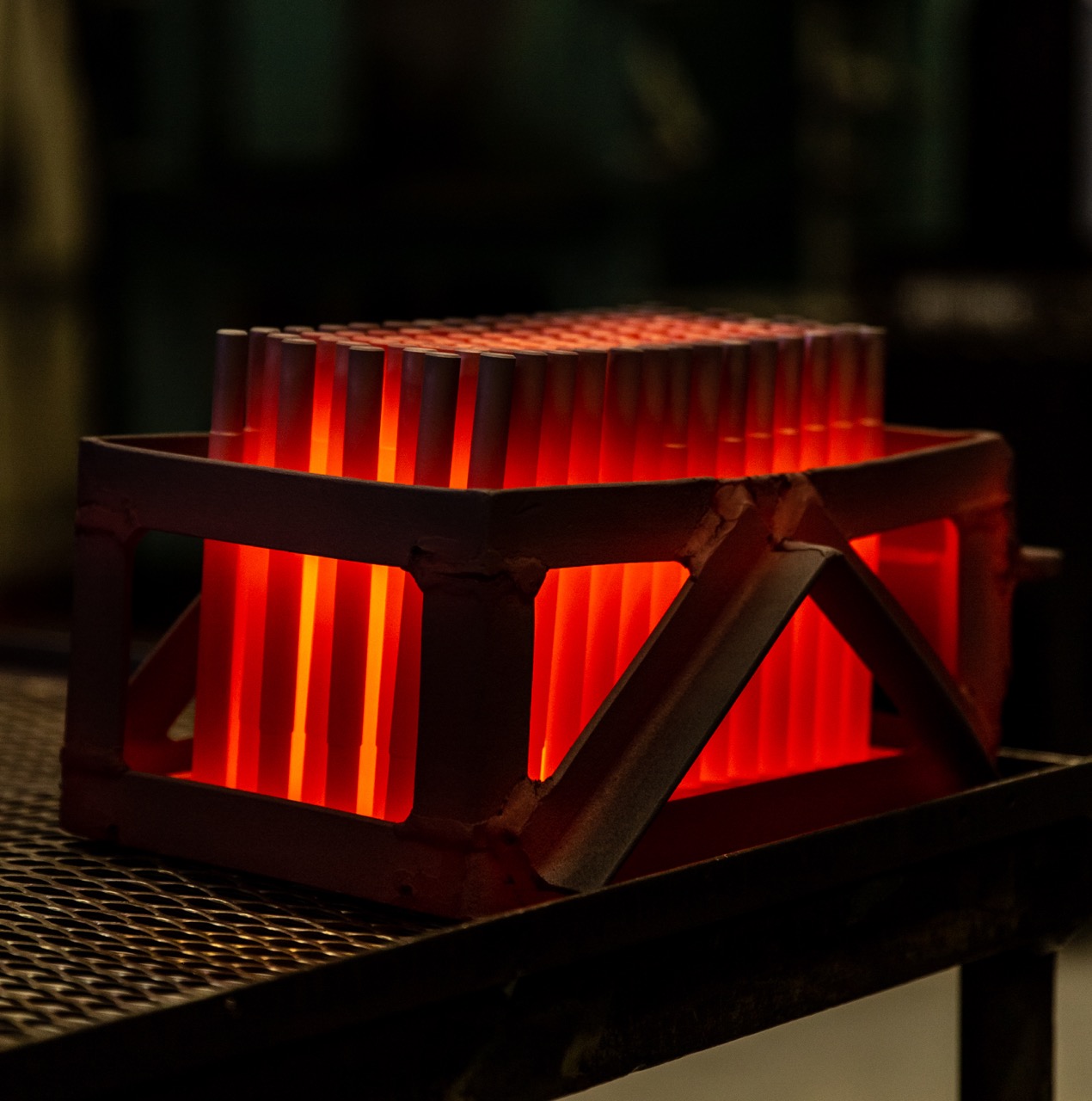

- Heat Treating of All Materials

- Internal Heat Treated and Annealed Using the Latest Technology to Gain Performance Benefits for all our Customers’ Unique Applications

- In-House Heat Treatment

- Oil Quench & Air Quench Options

- Nitrogen Freeze @ Tempering Phase of Heat Treatment

- RC/Hardness Documentation Upon Request

- Finishing/Polishing

- Part Straightening

Materials of Construction

Precision Ground Components are manufactured from:

- 300 SERIES STAINLESS

- 400 SERIES STAINLESS

- LOW CARBON STEELS

- H-13

- S-7

- A-2

- D-2

- M-2

- PM-M4

- A-11

- ALUMINUM – 6000/7000

- MOLDMAX HIGH HARD

- MOLDSTAR

- Other materials available

Don’t see what you’re looking for? Contact us today.